New to the world of 3D printing? Then the ride ahead is going to be quite fun for you.

Since its inception in the 1980s, 3D printing has come a long way both in the rapid evolution of the technology and also in wider application across industries. It was initially developed as additive manufacturing to aid prototypes. Today, from tooling aids to functional prototypes, 3D printing is being used in industrial and even everyday life as end parts.

Surge in popularity

The baseline is always cost. Technologies which are cost-effective and accessible, find many new applications, and enter wider outreach. Over the years, this highly expensive technology has seen many improvements that have brought down the cost of models and materials used in 3D printers effectively.

Variations in the functional aspect have made it a simple technology to use in many fields, whether it’s a bionic prosthetic, a part for your car, or children’s toy. It has become a practical tool now so that armed with a 3D printer, you can aspire to be a chef, inventor, or sculptor.

Recommended for you: How to Use 3D Modeling in Business Promotion & Advertising?

How does it work?

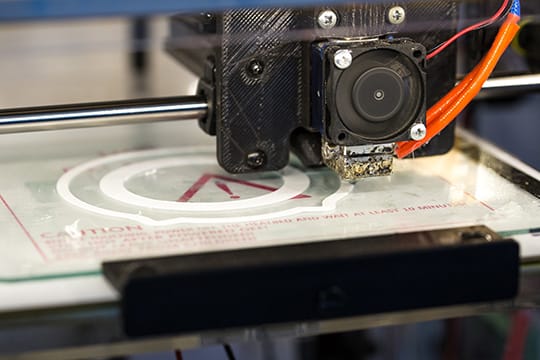

The 3D printing process is similar to paper printing when seen as the accumulation of different layers of materials laid down sequentially to create a solid three-dimensional object. It develops a 3D model single layer at a time, working from the bottom and makes its way upward. With repeated printing over the same area, the printer builds up a model over hours by turning a 3D CAD drawing into many two-dimensional, cross-sectional layers. Thus, a lot of separate 2D prints sit on top of one another, without the paper medium, and instead of ink as the material, it uses plastic.

Essentially, a 3D printer squeezes molten plastic through a tiny nozzle, a nozzle guided precisely through computer control based on a 3D design. It prints one layer, waits until its dry, and then prints the next layer on top it and within hours you get a 3D model!

Materials

3D printers use thermoplastics, especially the ABS variety. Think Lego! Now, this is a tough composite plastic, acrylonitrile, combined with synthetic rubber, butadiene styrene. Since the melting point is over 100°C (220°F) so that it’s solid at room temperature, it is a perfect material for 3D printing. Besides, ABS pigments really easily.

The theory, therefore, is that any molten material that will harden and set quickly in conducive temperatures can be used. Patents for materials include ceramics, clay, palladium, paper, rubber, silver, titanium, and wax to make a total of forty-five.

In the year 2011, molten chocolate in a 3D printer that brought chocolate desires to life-created waves.

Technologies used

There are seven different categories of 3D printing processes that have been recognized by ISO/ASTM 52900 standards. The standard developed in 2015, establishes terminology and printer classification standardization. These seven 3D printing processes have developed eleven different types of 3D printing technology that are presently used. These are Binder Jetting, DLP, DMLS, DOD, EBM, FDM, Material Jetting, MSLA, SLA, SLM, and SLS.

All the different technologies have their own design rules and the best 3D printing materials conducive to them. The most active technologies in use today are Fused Filament Fabrication (FFF) or Fused Deposition Modelling (FDM), and Stereolithography (SLA).

You may like: Print Media Business in Digital Age: Tips to Survive in 2019-2020.

Practical Uses

By the year 2015, many patents covering basic 3D printing technology expired. In recent years, there has been an explosion of new products, technologies, flexible 3D printing methods, and cost-effective equipment so that it is transforming industries around the world.

3D printing has become a practical tool in many areas. The 2020 COVID-19 pandemic has seen 3D printing technology quickly design and manufacture equipment. Applications of 3D printing can be found in the planning stages, tools development, and designing architect features. Many organizations have opted to run the whole end-to-end design process through it.

Some of the practical applications in current use are:

1. Education

Curriculums are incorporating 3D printing methods for creating ideas or images in the physical, 3-dimensional world. Designing and modeling without the need for expensive tools and in a faster, more secure environment. In fact, STEM education has been revolutionized with 3D printing tools that fabricate low-cost and quick prototypes. Similarly, students of archaeology, design, geography, and medicine gain a better perspective with it.

Curriculums are incorporating 3D printing methods for creating ideas or images in the physical, 3-dimensional world. Designing and modeling without the need for expensive tools and in a faster, more secure environment. In fact, STEM education has been revolutionized with 3D printing tools that fabricate low-cost and quick prototypes. Similarly, students of archaeology, design, geography, and medicine gain a better perspective with it.

2. Medical

Prosthetic limbs and even tissues, metal orthopedic implants with special porous characteristics that help patients to integrate easily, and bioprinting of artificial organs are all contributions of 3D printing technology. Pharmaceutical testing on 3D printed tissues is not only cost-effective and time-saving but also an ethical step in medical testing procedures. In fact, Binder Jetting technology is producing porous pills for higher dosage applications.

Prosthetic limbs and even tissues, metal orthopedic implants with special porous characteristics that help patients to integrate easily, and bioprinting of artificial organs are all contributions of 3D printing technology. Pharmaceutical testing on 3D printed tissues is not only cost-effective and time-saving but also an ethical step in medical testing procedures. In fact, Binder Jetting technology is producing porous pills for higher dosage applications.

3. Manufacturing parts

The auto industry along with other industries has been hugely benefitted by the 3D printing tools manufacturing spare parts. Imagine a part that is no longer in production, the replacement can be designed and printed fairly easily. Now, companies can and do offer greater customization services. You can custom design objects through simple web-based customization software, and place an order for the resulting item. Think unique mobile cases, light fixtures, etc.

The auto industry along with other industries has been hugely benefitted by the 3D printing tools manufacturing spare parts. Imagine a part that is no longer in production, the replacement can be designed and printed fairly easily. Now, companies can and do offer greater customization services. You can custom design objects through simple web-based customization software, and place an order for the resulting item. Think unique mobile cases, light fixtures, etc.

4. Construction

Printable 3D homes are pre-fabricated prototypes that can be installed at various sites. New collaborations and advancements in the technology of printers are bringing down costs gradually. The move from concrete to innovative concrete mixes are helping to develop better and more affordable products. There are many different types of construction 3D printers, from polar machines to gantry-mounted printers to mobile robots. 3D printed homes can be a solution for the housing crisis, especially in rural areas that are impacted by inclement weather.

Printable 3D homes are pre-fabricated prototypes that can be installed at various sites. New collaborations and advancements in the technology of printers are bringing down costs gradually. The move from concrete to innovative concrete mixes are helping to develop better and more affordable products. There are many different types of construction 3D printers, from polar machines to gantry-mounted printers to mobile robots. 3D printed homes can be a solution for the housing crisis, especially in rural areas that are impacted by inclement weather.

5. Art and design

Artists all over the world have been inspired by 3D printing and have embraced the technology to produce individual and unique products. From interior design and home décor to jewelry and sculptures, experimenting with designs has become a cost-effective process. Many artists are rendering 3D versions to mediums that aren’t visual like voices or songs, or intangible to blind people like paintings, etc.

Artists all over the world have been inspired by 3D printing and have embraced the technology to produce individual and unique products. From interior design and home décor to jewelry and sculptures, experimenting with designs has become a cost-effective process. Many artists are rendering 3D versions to mediums that aren’t visual like voices or songs, or intangible to blind people like paintings, etc.

6. Personal uses

In everyday life, more and more things are being 3D printed. Many household goods and tools of varied sizes, shapes, or colors can be rendered at home. A 3D printer allows you to print replacement parts at home, rather than ordering them. What about a stand or shelf or bracket that would precisely suit the corner of your room? Think of additions to your cosplay outfits, fashion accessories, or design toys and imagine new games!

In everyday life, more and more things are being 3D printed. Many household goods and tools of varied sizes, shapes, or colors can be rendered at home. A 3D printer allows you to print replacement parts at home, rather than ordering them. What about a stand or shelf or bracket that would precisely suit the corner of your room? Think of additions to your cosplay outfits, fashion accessories, or design toys and imagine new games!

7. Food

3D food printing is restricted to tracing single edible pastes into precision shapes determined by a 3D model and slicing software instructions. Filament materials also referred to as food cartridges range from food pastes like bean pastes, cookie dough, jams, mashed potato to cassis, chocolate, fondant, marzipan, and pasta. They come pre-loaded with recipes and templates. In the larger industrial applications, food can even be customized in texture, flavor, or nutrition, making them useful for fields like space exploration and healthcare.

3D food printing is restricted to tracing single edible pastes into precision shapes determined by a 3D model and slicing software instructions. Filament materials also referred to as food cartridges range from food pastes like bean pastes, cookie dough, jams, mashed potato to cassis, chocolate, fondant, marzipan, and pasta. They come pre-loaded with recipes and templates. In the larger industrial applications, food can even be customized in texture, flavor, or nutrition, making them useful for fields like space exploration and healthcare.

A new form of expression has achieved output due to the availability of 3D printers. Its time you put your own 3D printer to use creating designs that could give a flair to your design aptitudes and a boost to practical usage.

Why you should get one?

The ease of using 3D printers is slowly eroding the ‘why to use a 3D printer at home’ question, many people have. If you are a hobbyist, it’s time for some value addition to your skills with CAD software skills. Better still, the online availability of a wide range of printable designs can give you the ideas to open up a small business from home. Think personalized gifting options!

The ease of printing spare parts and replacement items reduces dependence on expensive shipping deliveries and waiting periods. You get quicker access to items and even add your own design changes and modifications. It is also a great learning and training tool for children, in fact, any age group.

You may also like: Will 3D Animation End the Tide for 2D Animation? Let’s Find Out!

Get the inspiration

All the things you do every day either in your home or in your office could be made easier with a 3D printer. For instance, let’s say you are looking for a simple wall bracket near your work desk at home to hang the headphones. You don’t need to browse an online shopping portal, just download pre-made designs from the internet and print them! Many household items have a printable version of them online.

“The practical uses and professional applications of 3D printing are very inspiring. It isn’t only for tech-savvy entrepreneurs. There are many practical uses that can improve your home and how you live in it. You can figure out uses for your own 3D printer at home.” – as mentioned by Shoei Yamana, the President of Konica Minolta, in one of his recent interviews.

Now that you are mulling over the buying of a 3D printer, 3D printing through online courses can be a learning step. Online videos are also available so you can learn from these videos as well.